ZPS - GENERÁLNÍ OPRAVY, a.s. complete overhauls and modernization of multispindle automatic lathes

MODERNIZATION OF LATHES ANS MACHINE TOOLS

Modernization and replacement of electricity

- replacement of the switch controlled by means of mechnical cams with a new electronic position indicator of the curved shaft with cam-less control of lathe functions

- replacement of relay control of lathe functions by programmable PLC SIEMENS automat with diagnostics of failures watched in automatic cycle

- installation of a new control panel with display, to display lathe operations, switching-off of shits can be set when the life of individual tools comes to an end

Modernization and providing the lathe with the drive of programmable independent AC SIEMENS motors for lathe speeds and feeds

- smooth regulation of the lathe working run (cycle time) in dependence on the needs of the technological procedure, controlled directly from the lathe panel (that means the lathe will be without change gears)

- decreasing of the lathes noise

- shortening of the non-priductive idle time of the lathe for about 30%

- stabilization of the moment of the working run switch-over to non-working run and vice versa, independent of the lathe temperature, with the possibility to change the angle of the above switch-over directly from the lathe control panel

- providing the lathe with auxiliary turning over of the lathe shifts (at adjustment and replacement of tools) under three different speeds - microshift, middle speed shift, high-speed shift, in both directions, controlled from the lathe panel

- control panel will be equiped with display, to display lathe operations. At the same time the above will enable calculations of cutting speeds and shifts to lathe revolutions in dependance on the specified working time

- drop of lathe maintenance requirements due to the absence of the shifting and high-speed shifting clutch and shifts brake

- optionally, the lathe can be equipped so that two different working times can be used under one lathe cycle

- controlled motors will have a mechanical brake built it. This brake is put into operation in case electrical energy drops or falls-out and it will brake all the shifts. By this safety regulations are met.

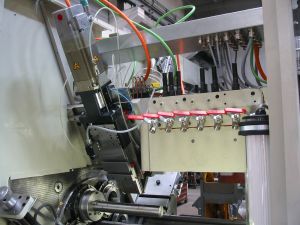

CNC Slides

We have many experiences with general overhauls of multispindle lathes, where we make a changeover of slides into CNC slides. Such modernisation means many advantages for customer, including better accuracy, quicker adjustment, lower costs and others. We have experiences with this transformation into CNC lathes with many types ofmultuspinle lathes.